Getting more blueberries from the field to the grocery store, without hurting their quality, is the focus of a new nationwide research project led by a faculty member in the University of Georgia College of Engineering.

Changying “Charlie” Li, an associate professor who specializes in sensor technology, is leading a four-year study designed to identify ways to improve the efficiency of the nation’s blueberry harvest. Last fall, the U.S. Department of Agriculture awarded a $2.37 million grant to Li and his colleagues at 10 universities across the nation for the project.

Among the research team’s goals: develop a new, affordable “semi-mechanical” blueberry harvester, use sensor technology to identify plant varieties most suitable to mechanical harvesting and use an electronic “berry” to analyze the bumpy path the fruit travels before reaching the produce aisle.

“The U.S. is the top blueberry producer in the world, accounting for more than two-thirds of all production,” Li said. “Just last year, Georgia became the top blueberry producing state.”

Despite this blueberry boom in the Peach State and elsewhere across the nation, growers face several challenges. Li said the increasingly high cost of labor, a shortage of workers and low harvest efficiency could create a bottleneck for further growth in the industry.

“Nearly all fresh market blueberries are harvested by hand, because machine harvesters damage the fruit too much and the quality is too low to be sold as fresh fruit in the supermarket or grocery store,” Li said.

The lower quality fruit ends up in processed foods such as blueberry bagels or blueberry pancake mix. According to Li, these berries often bring farmers half the price of the higher quality handpicked fruit.

While mechanical harvesters reduce harvesting costs substantially, existing machines have several drawbacks, according to Fumiomi Takeda, a member of the research team. Takeda is a research horticulturist at the USDA’s Appalachian Fruit Research Station in Kearneysville, West Virginia.

“Over-the-row mechanical harvesters can pick blueberries quickly, but they can cost up to $170,000,” Takeda said. “That’s simply unaffordable to small- and medium-size berry growers. In addition, the berries harvested by these machines are quite often bruised and have a short shelf-life.”

The harvesters also contribute to yield losses as a significant amount of fruit falls to the ground.

To address the challenge of increasing yield and lowering costs while maintaining quality, Li, Takeda and their colleagues are designing a semi-mechanical harvester. Li believes the technology could increase the efficiency of the blueberry harvest tenfold, significantly reduce labor costs and lead to lower prices for consumers.

The team’s harvester design features a catch plate and conveyor system. As the machine rolls along rows of blueberry bushes, Li envisions a worker riding along with a specially designed “shake stick.” As the worker shakes the bush, the ripe berries fall onto the catch plate. To protect the berries as they fall, the machine generates a gentle cushion of air, like an air hockey table.

Li and his team plan to develop a prototype of the harvester by the end of the year.

The research team includes two faculty members in the UGA College of Agricultural and Environmental Sciences: Harald Scherm, a professor of plant pathology and assistant dean for research, and Jinru Chen, a professor in the food sciences and technology department.

Scherm’s role in the project is to investigate the risk of postharvest fruit rot in relation to various harvesting and postharvest handling technologies.

“Blueberries can develop postharvest fruit rot especially if they are bruised during the harvesting process or on the packing line,” he said. “We’ll collect fruit samples picked with the various harvester designs developed as part of this project. We’ll follow them over time in postharvest cold storage to determine the level of infection with various postharvest pathogens.”

This part of the project will help the team determine whether the new harvester designs are capable of harvesting fruit more gently, thereby reducing postharvest rot.

Other institutions participating in the project are also located in major blueberry producing states: the University of California, Berkeley; the University of Florida; Michigan State University; Mississippi State University; North Carolina State University; Oregon State University; Penn State University; Washington State University; and the USDA Agricultural Research Station in Kearneysville, West Virginia.

Li says the team is “attacking the challenge from every possible angle.” Its members include engineers, microbiologists, horticulturalists, economists and an expert in ergonomics.

A second focus of the project involves using sensor technology to measure the damage blueberries experience as they move from the harvest through the packing process.

“When you harvest blueberries, especially with mechanical harvesters, and when you process, sort and pack them, their quality will degrade. That’s intuitive, but it’s also been documented by research,” Li said. “We want to quantitatively measure those types of impacts induced by mechanical harvesters and packing lines.”

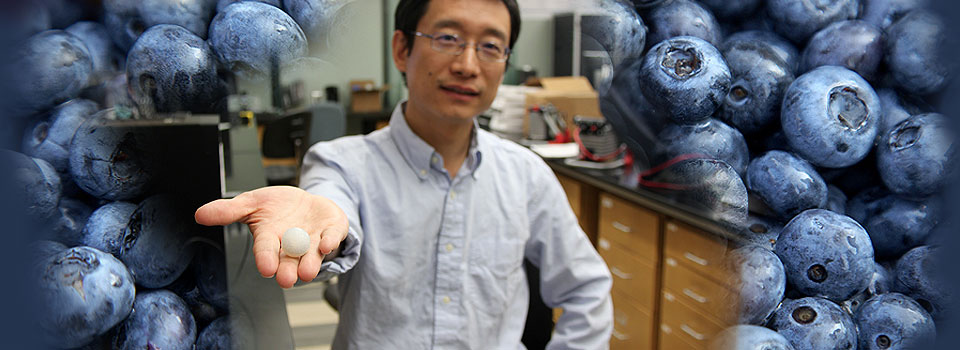

To get a firsthand account of what blueberries experience in packing plants, Li has developed the Berry Impact Recording Device, or BIRD. Slightly larger than a blueberry, the off-white ball rides along with the berries in the plant while its electronic chip records the bumps and bruises inflicted on the fruit. Li says data gathered by BIRD will help engineers analyze and improve the design of packing lines.

—Mike Wooten, College of Engineering