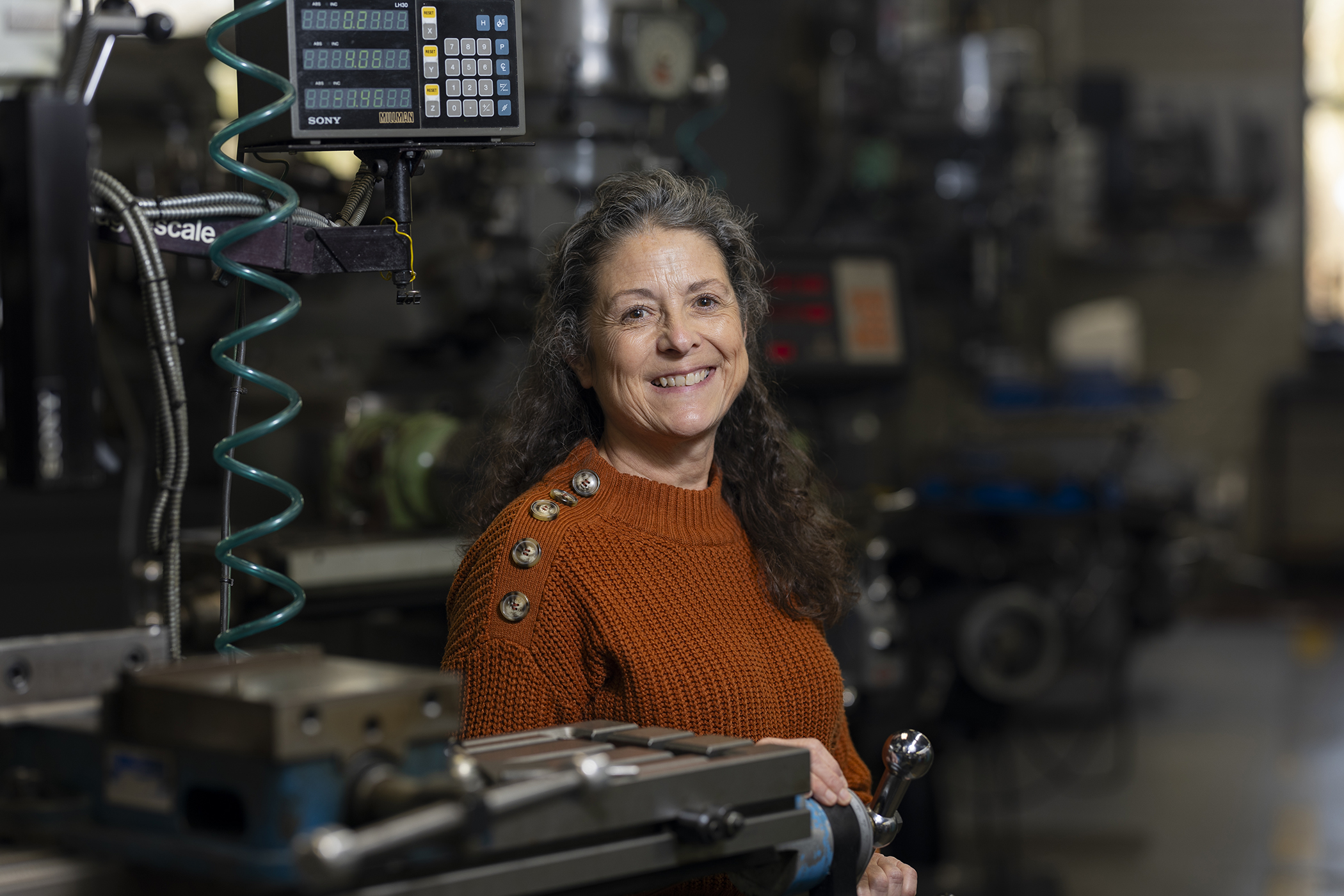

Terri Barber is the wizard behind the curtain.

As the business manager at UGA’s Instrument Design and Fabrication Shop, she oversees the daily functions of accounting and procurement to ensure the team has the numerous tools and materials needed to be used for various research projects that are presented.

“You never know what’s coming in the door,” Barber said, describing the process from start to finish. “The researchers and students come in, and they have these ideas. Sometimes they won’t know exactly how to put them on paper, or they have the drawing on a napkin. They sit down with our designer and next thing you know, we have this magnificent piece of equipment.”

That process continues to bring enjoyment to her job. Since she was a child, Barber has been interested in how things are made. Growing up in Athens, when she wasn’t singing in church and on radio shows, she was with her grandfather, learning what made things tick. She worked with the university to repair computers for two years before moving to the Instrument Design and Fabrication Shop in 2008.

The instruments that Barber oversees serve many purposes. The shop produces everything from small tools such as renal clips for rats to big machines that go under the ocean. One of her favorite projects is currently at Zoo Atlanta.

“I love animals, and the zoo in Atlanta has one of our projects in their gorilla display,” Barber said. “It’s a termite mound that’s used to encourage social interactions. They don’t use termites, though; they use peanut butter.”

During the COVID-19 pandemic, Barber and the shop’s team members helped to make hundreds of face shields for health care workers.

“We were very proud, and they were really pleased with the shields,” Barber said. “Even though they were so busy, they took the time out of their day to send us photos and tell us how much they appreciated it.”

Along with keeping up with payroll and shop inventory, Barber ensures that team members have exactly what they need to complete projects. The shop uses different types of metals and plastics to create the instruments that researchers request. They work with 3D printers, a laser cutter, water jet and a variety of CNC equipment. While the team crafts each piece, she works to find the best material for each project at the best price.

“The most important part of my job is finding a way to help save money by getting the best quality best product at the best cost while adhering to procurement policies,” Barber said. “I save the researchers money so they can make more unique equipment to do more teaching, be more creative and find ways of making our world better.”

In her free time, Barber enjoys hiking and spending time with her family. She has hiked in numerous mountains around Georgia, Tennessee and South Carolina, even venturing to the mountains of Alaska.

No matter how far she travels, Barber still appreciates the great ideas and projects that come to and from the shop.

Barber invites more researchers to the Instrument Design and Fabrication Shop to visit the wizard behind the curtain for their research projects.

“The instrument shop is the most amazing and interesting research facility for your ideas,” Barber said. “Bring them all here. We can make it happen.”