AI can improve manufacturing in many ways, but it’s a challenge for companies to implement when trial and error is on the table.

That’s where the UGA Innovation Factory comes in.

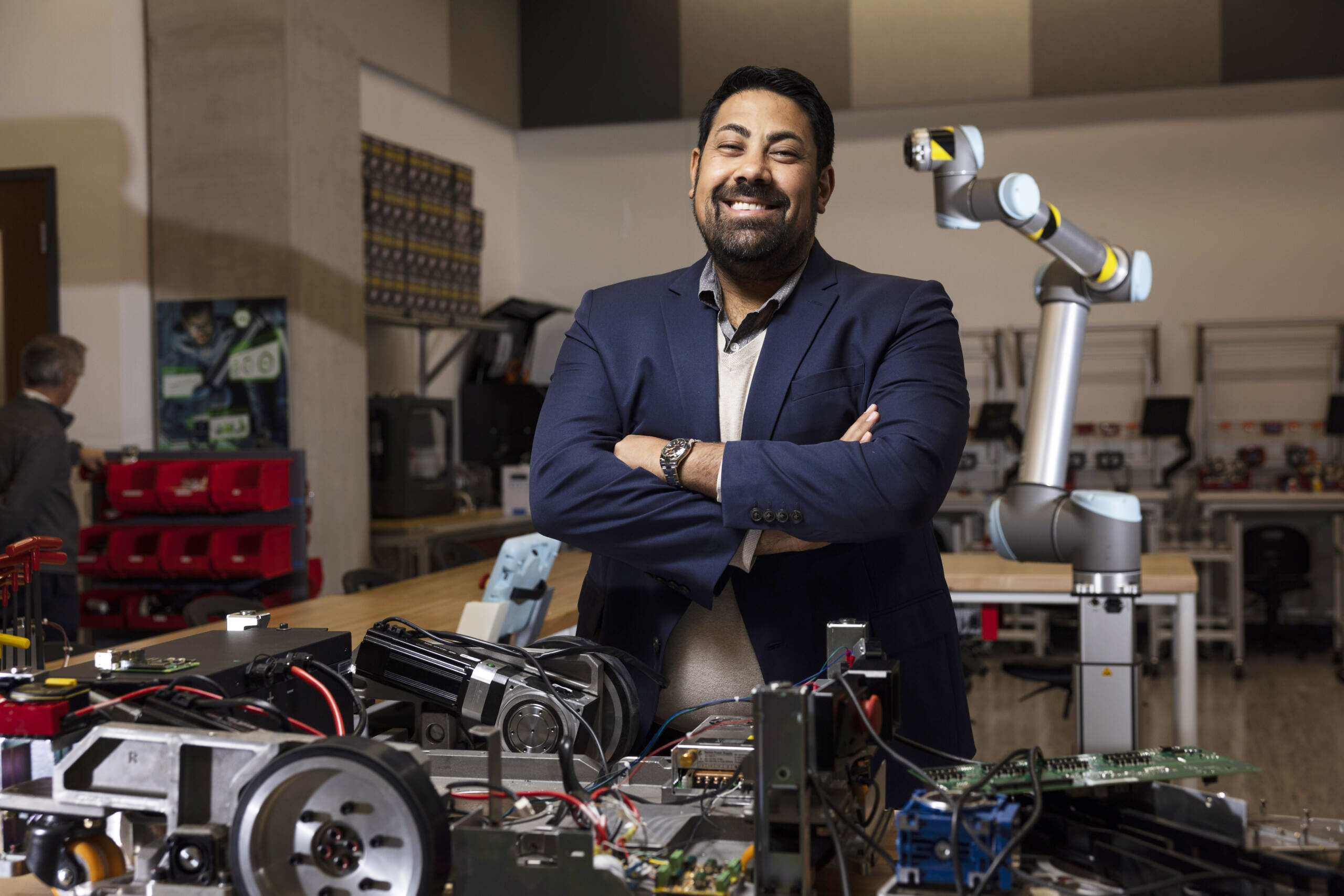

This space in the Interdisciplinary STEM Research Building 1 features some of the latest AI technology, as well as simulated factory lines, allowing UGA students and researchers to experience firsthand how different technologies interact with factory operations and meeting goals of research, teaching, and industry engagement, says Beshoy Morkos, an associate professor in the College of Engineering whose research centers on system design and manufacturing.

“We are leading conversations surrounding AI, recognizing the importance of addressing its concerns before collaborating with companies,” Morkos says. “There can be concerns about AI’s impact on jobs and job displacement, and we’ve seen what AI has allowed us to do: It’s not job elimination; it’s job transformation.”

Ongoing projects include monitoring assembly stations for down time and work status, as well as integrating a robotic inventory management system, and these are just a few examples of how AI can be utilized in a factory setting. The lab also looks at how these technologies are best introduced to workers and how programs can improve efficiency as well as worker experience.

The ultimate goal, Morkos says, is to understand how technology can take over repetitive or mundane tasks in order to elevate workers to more complex roles.

There can be concerns about AI’s impact on jobs and job displacement, and we’ve seen what AI has allowed us to do: It’s not job elimination; it’s job transformation.” — Beshoy Morkos, associate professor in mechanical engineering

“It’s our moral obligation as scientists to think about our next generation of manufacturing facilities and what tomorrow’s workplace is going to look like,” he says. “We do that while being socially conscious, and that helps us be technologically relevant and competitive, both in the national and global landscape.”